Stress Relaxation in 3D Printing Materials

Summary

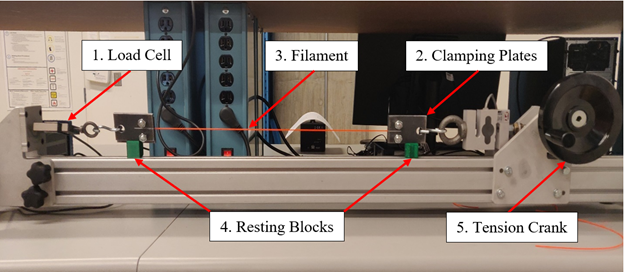

The inspiration for this project is that a filament spool holder I was working with uses torsional springs to auto-retract filament into a spool when using a Prusa Multifilament extruder. From my testing, I found that PLA would relax too much, resulting in the springs failing, but I wanted to find what material I had that would have the best performance when used as springs. The best way to test this was to test the raw filament, so we built the test apparatus shown in the figure below. It comprises a load cell, a crank and two filament mounting plates that maximize the contact area and reduce slippage.

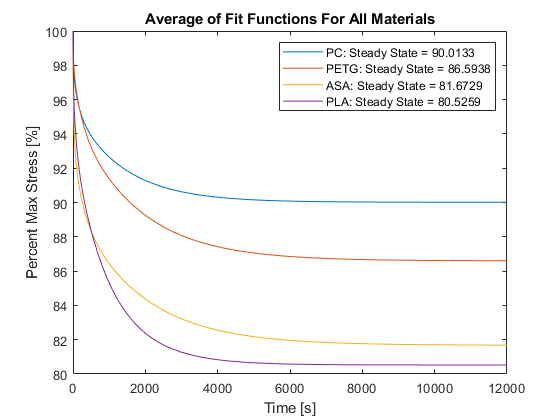

The data was collected using a custom Matlab script I wrote to record the time series force data and store it in a CSV for later processing. With the raw data, I created a processing script to crop the data to the peak force and scale everything to be a fraction of the max force. Scaling all the data to be a percentage of peak made comparing the data between tests simpler because all tests started at 100% stress at time equals zero. Through my research, we would expect the material’s stress relaxation to follow an exponential Prony series, which is the sum of exponential decays with different weights and time constants. We collected five datasets on four different materials and, using the fit method, were able to plot the average response of every material shown in the plot below.

From this, the best options would be PC at $50/kg or PETG at $30/kg, as they have the best steady-state values for each price point. Please refer to the report below or the repository with raw data and code.